Threat Monitoring & Response for Industrial Equipments

Contact SalesBackground

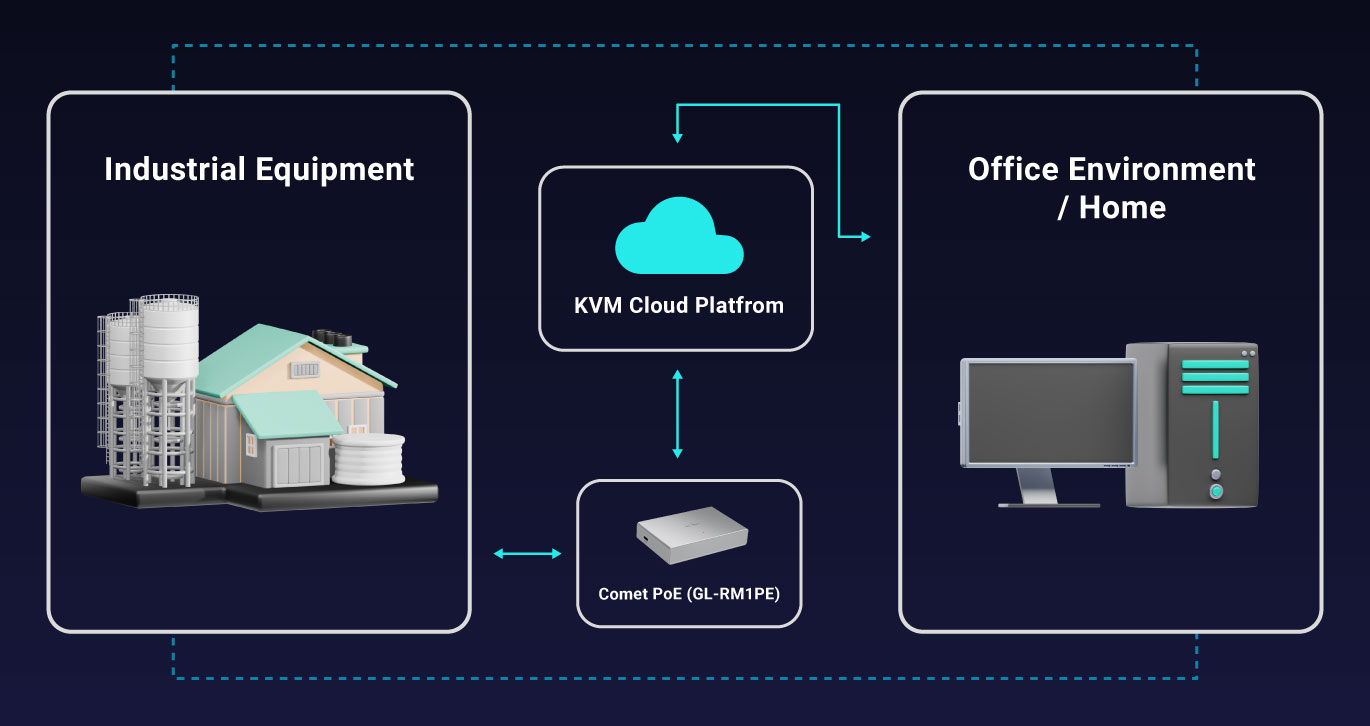

Industrial control equipment management is critical to chemical plant operations, with its efficiency and data reliability directly impacting production safety and operational costs. Despite daily inspections, a chemical plant struggles with undocumented faults, slowing anomaly response (e.g., pH irregularities) and requiring costly offsite repairs due to offline equipment. To mitigate these safety and cost challenges, the plant plans to deploy a KVM system for secure, real-time equipment monitoring and data management.

Challenges

Inefficient Operations

Managing numerous distributed devices through manual inspections is slow and inefficient, exacerbated by the need for equipment to withstand high noise, heat, and other demanding conditions

Safety and Accessibility Risks

The high-risk environment requires minimizing personnel site visits, while traditional offline equipment restricts remote support, increasing safety concerns and operational delays

Limited Remote Management

Lack of connectivity prevents traditional remote control, forcing costly on-site repairs or ineffective phone support—resulting in extended downtime, higher expenses, and reduced operational oversight

Solution

GL.iNet's KVM technology has changed industrial O&M through its remote management and maintenance system. Its core value lies in leveraging existing display and input interfaces for remote control without requiring equipment modifications or additional hardware/software installation, making it compatible with all types of industrial devices.

Significant Reduction in Operational Costs

- 1. Significant reduction in annual maintenance and labor costs through O&M model transformation

- 2. KVM-enabled remote ops center replaces physical equipment monitoring, allowing home-based shifts that reduce staffing needs while maintaining 24/7 coverage

- 3. Flexible deployment with PoE support to reduce cabling and simplify retrofitting

Dramatic Improvements in Safety and Response Efficiency

- 1. Real-time control room monitoring with instant hazard response - replacing manual patrols with faster emergency intervention

- 2. Physical isolation of personnel from dangerous environments

- 3. Custom firmware + audit trails for risk control and full accountability

Intelligent O&M Management System

- 1. Full-stack monitoring from hardware-level OOB management to cloud analytics

- 2. Fault-tolerant architecture with BIOS-level recovery and management, enabling deep reboots and complete log tracing for mission-critical systems

- 3. Remote remediation support via KVM, allowing industrial equipment manufacturers to diagnose and repair systems in real-time

Results

The deployment of GL.iNet's KVM into the management system resulted in substantial improvements across key operational metrics by reducing repair times, eliminating on-site visits and increasing operator productivity.

Product Details

Contact Our Sales Team

You're more than a customer. You're our business partner. We're here to help!